Anwenderbericht

Achenbach Buschhütten GmbH & Co. KG

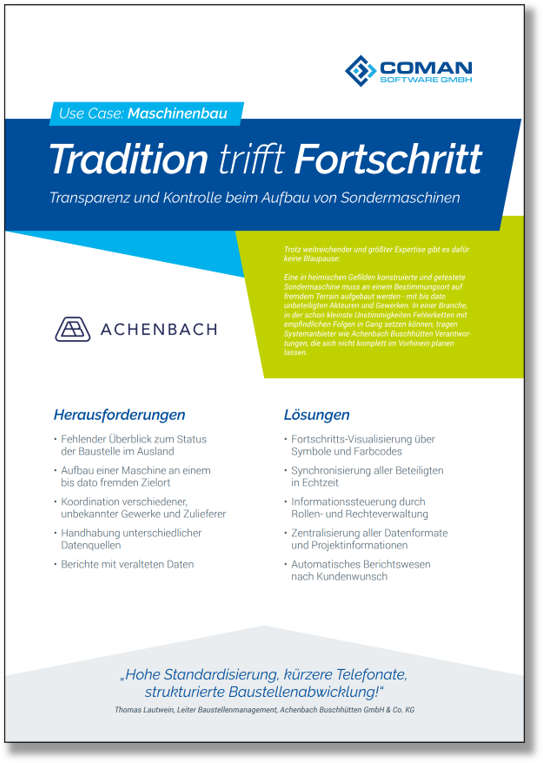

Use Case: Maschinenbau

Das Familienunternehmen hat sich in der Vergangenheit einen Namen mit mehreren Weltmarktführerschaften gemacht. Sie fertigen Folienschneidmaschinen für die Nicht-Eisen-Metall- und Veredlungsindustrie in über 60 Ländern, in denen unterschiedlichste Bedingungen gelten. Bei Achenbach nutzt man seit 8 Generationen Lösungen auf der Höhe der Zeit, die sie in die Zukunft geführt haben. Erfahren Sie hier, welche Rolle COMAN dabei seit 5 Jahren spielt.

Zum Anwendungsfall

Trotz weitreichender und größter Expertise gibt es dafür keine Blaupause: Eine in heimischen Gefilden konstruierte und getestete Sondermaschine muss an einem Bestimmungsort auf fremdem Terrain aufgebaut werden – mit bis dato unbeteiligten Akteuren und Gewerken.

Erfahren Sie in diesem Anwenderbericht, wie Maschinenbauer mehr Kontrolle über ihre Baustellen erlangen und dabei mit Widrigkeiten umgehen können, die sich nicht komplett im Vorhinein einplanen lassen.

Dieser Anwenderbericht ist für

- Maschinenbauer

- Baustellenmanager

- Baustellenleiter

- Projektplaner

- Projektleiter

- Montageleiter

- Claims-Manager

„Hohe Standardisierung, kürzere Telefonate, strukturierte Baustellenabwicklung!“

Leiter Baustellenmanagement, Achenbach Buschhütten GmbH & Co. KG

Thomas Lautwein

Herausforderungen

- Fehlender Überblick zum Status der Baustelle im Ausland

- Aufbau einer Maschine an einem bis dato fremden Zielort

- Koordination verschiedener, unbekannter Gewerke und Zulieferer

- Handhabung unterschiedlicher Datenquellen

- Berichte mit veralteten Daten

Lösungen

- Fortschritts-Visualisierung über Symbole und Farbcodes

- Synchronisierung aller Beteiligten in Echtzeit

- Informationssteuerung durch Rollen- und Rechteverwaltung

- Zentralisierung aller Datenformate und Projektinformationen

- Automatisches Berichtswesen nach Kundenwunsch

DOWNLOAD

Direkt zum Achenbach Anwenderbericht

Bitte füllen Sie das Formular aus, um den Kundenbericht herunterzuladen