As a global provider of intelligent automation systems, Valiant TMS plays a key role in international automotive plant engineering.

TMS Turnkey Manufacturing Solutions GmbH – the group’s organizational nerve center in Europe – develops, builds and integrates automated production systems and tools for all body-in-white areas. Discover how international challenges are managed from the Linz site.

About the case

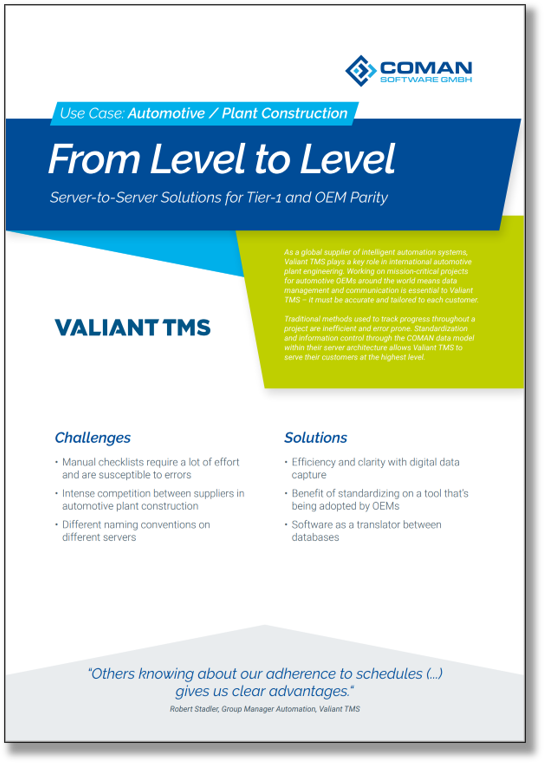

Working on mission-critical projects for OEMs around the world means that data management and communication must be tailored to each customer. In addition, there is the coordination of a large number of sub-suppliers that are highly interdependent. We illustrate how Valiant TMS serves each of its customers with standardization at the highest level, giving it an edge in a highly competitive industry.

This customer story is for

- Turnkey Plant Manufacturers

- Automotive Suppliers

- Automation Specialists

- Group Managers

- Commissioning Engineers

- Process Managers

- Digitization and Innovations Managers

“Others knowing about our adherence to schedules (…) gives us clear advantages.”

Challenges

- Manual checklists require a lot of effort and are susceptible to errors

- Intense competition between suppliers in automotive plant construction

- Different naming conventions on different servers

Solutions

- Efficiency and clarity with digital data capture

- Benefit of standardizing on a tool that’s being adopted by OEMs

- Software as a translator between databases