As a global provider of intelligent automation systems, Valiant TMS plays a key role in international automotive plant engineering.

TMS Turnkey Manufacturing Solutions GmbH – the group’s organizational nerve center in Europe – develops, builds and integrates automated production systems and tools for all body-in-white areas. Discover how international challenges are managed from the Linz site.

About the case

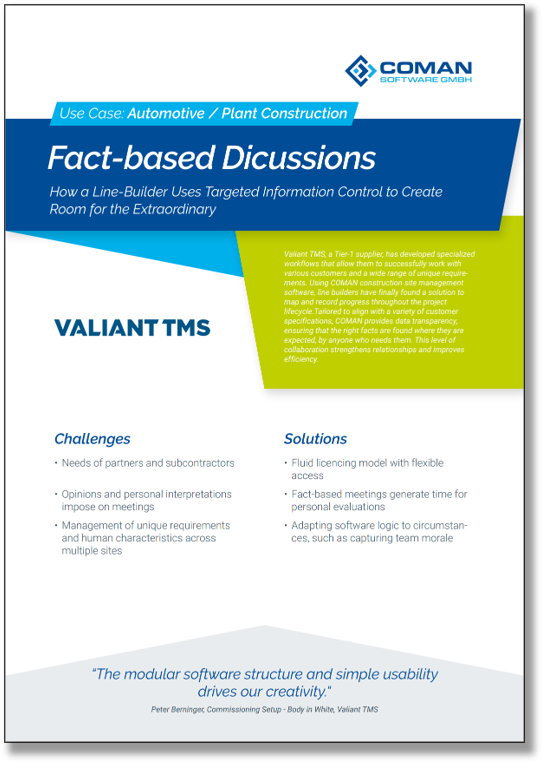

Tier-1 supplier Valiant TMS stands for its own methods, which it applies across all projects. Find out how the line builders found and established their system to record deadlines and progress, easily map various dependencies, and deliver to stakeholders with reduced complexity. This not just saves time, but also provides capacity for vital topics that often receive too little attention.This customer story is for

- Body-in-White Line Builders

- Automation Specialists

- Automotive Suppliers

- Site Managers

- Site Coordinators

- Project Managers

- Team Leaders

“The modular software structure and simple usability drives our creativity.“

Commissioning Setup – Body in White, Valiant TMS

Peter Berninger

Challenges

- Needs of partners and subcontractors

- Opinions and personal interpretations impose on meetings

- Management of unique requirements and human characteristics across multiple sites

Solutions

- Fluid licencing model with flexible access

- Fact-based meetings generate time for personal evaluations

- Adapting software logic to circumstances, such as capturing team morale