Optimal Solution for Mechanical and Plant Engineering Projects

Absolute Control from Conception to Acceptance

COMAN has been an integral part of plant and mechanical engineering for years. Centralize project data, digitize analog processes and always keep an overview.

With COMAN, you control your projects worldwide from the initial planning, to the on-site construction, to the handover of the keys to the satisfied customer.

Well known Scenarios

Pre-assembled and tested elements often have to be installed precisely on the other side of the world. One works with unknown teams, in different languages, not infrequently with only a moderate Internet connection. Nevertheless, the work has to be done on time and smoothly.

Issues and challenges:

- Lack of overview of the construction status

- Coordination of different unknown teams

- Lack of communication due to language barriers

- Obsolete reports, different data sources

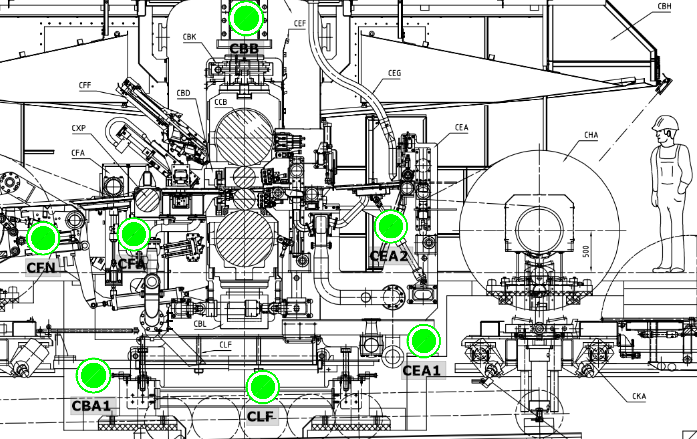

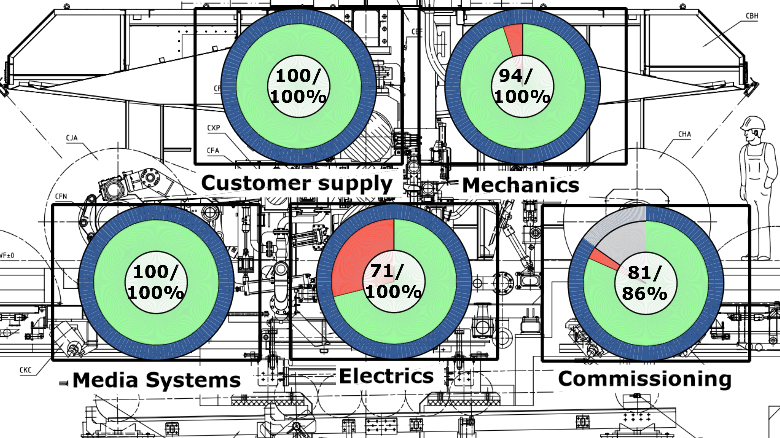

Accurate Representations

Clear Statements Coordination

Suppliers and trades must be efficiently coordinated, tasks clearly defined. It requires accurate progress recording with targeted information control.

Solutions:

- Progress recording with visual support

- Clear allocation of roles, rights and responsibilities

- Central data formats and project information

- Real-time synchronization of all stakeholders with automatic reporting

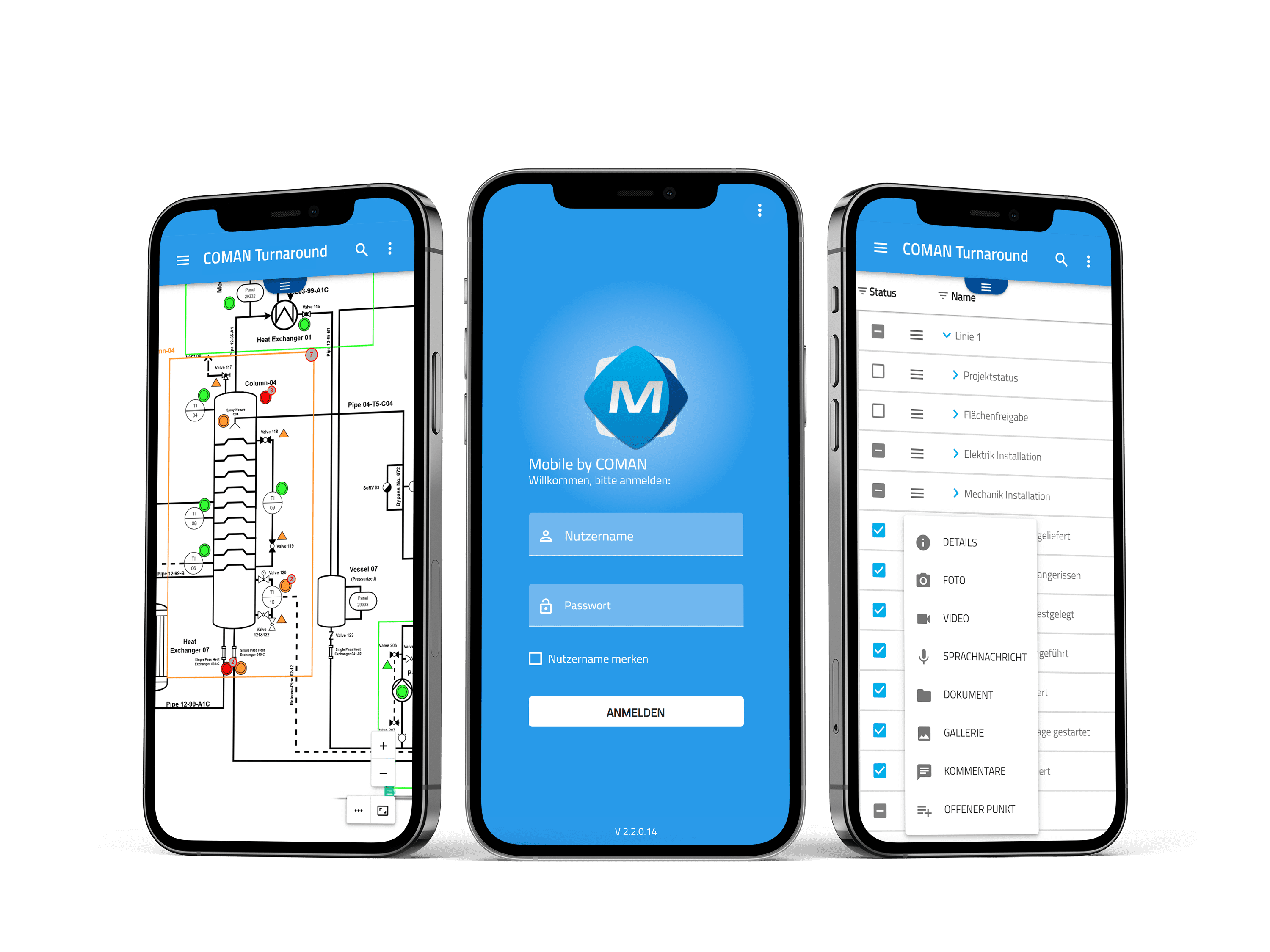

The whole Project

all Tasks

all Info on 6,5 inch

COMAN creates a clear system with a clear distribution of rights and roles. Visualization via symbols and color codes avoids language barriers. Use the mobile app and manager to monitor projects on the go and control them from anywhere.

COMAN Support:

- Centralization of quantity structures, deadlines and processes

- Comprehensible claim management even without

IT knowledge - Off-line usability and multi-usability to bridge unwanted delays

- Immediate exchange of information between

all involved

Your advantages by using the COMAN

CEOs and Directors

Higher flexibility and well-founded decisions for CEOs and directors with COMAN

With COMAN, CEOs and directors can monitor daily operations and make work processes more efficient. Project planning is supported and machine and plant construction is managed smoothly. By closely monitoring project progress and processes, well-founded decisions can be made.

COMAN is the project management tool for the turnkey construction of machines and makes projects successful from start to finish.

Department Manager

Optimal project management for department managers in plant engineering with COMAN

COMAN offers great benefits to plant engineering department managers, including pre-fabrication, assembly, production and commissioning managers.

COMAN optimizes task coordination and collaboration between teams. It simplifies the transparent and reliable management of commissioning and the clear definition and tracking of project goals in terms of quality, deadlines and costs.

Site Manager / Construction Site Manager

Efficient construction management with COMAN: digital monitoring and reports

As a site manager or construction site supervisor, you can use COMAN to collaborate efficiently within the construction site team, digitally monitor construction progress, create digital protocols and easily record open points and digital reports.

COMAN is the construction site management system for transparent monitoring, control and coordination of all those involved in the construction of machines and systems.

Project Manager

Efficient project management with COMAN software for project managers, planners, coordinators and schedulers in the plant engineering industry!

With COMAN, project managers benefit from seamless team integration and effective collaboration. The platform enables clear roles, rights and responsibilities to be assigned so that everyone knows exactly what needs to be done. Open points can be optimally tracked and processed, deadlines can be coordinated with suppliers and checklists can be tracked precisely to keep an eye on project progress at any time. Optimize your project management with COMAN and experience the difference!

Quality Management

Optimized quality ensure with COMAN

With COMAN, quality managers can easily track, record and report open issues on site via a mobile app. Photos, videos, comments and detailed descriptions of problems can be added to the app. In addition, checklists can be filled in.

COMAN is the construction site management system for the transparent monitoring, control and coordination of all parties involved in the construction of machines and systems.

Assembly Teams

Digital progress in plant engineering with COMAN

COMAN offers assembly teams in plant construction decisive advantages through digital planning, control and monitoring of pre-assembly through to final assembly on site at the customer's location. The software facilitates the creation of digital documents, shows clear workflows and enables the targeted filtering of relevant data. COMAN thus provides effective support in increasing quality and reducing errors throughout the whole assembly process.

Suppliers

Smooth cooperation and uncomplicated scheduling for suppliers

With COMAN, suppliers and clients can work together on a collaborative platform without much effort, request changes to deadlines and document progress easily via app. With COMAN, there is no longer a need to use countless emails or Excel lists as reports.

Higher flexibility and well-founded decisions for CEOs and directors with COMAN

With COMAN, CEOs and directors can monitor daily operations and make work processes more efficient. Project planning is supported and machine and plant construction is managed smoothly. By closely monitoring project progress and processes, well-founded decisions can be made.

COMAN is the project management tool for the turnkey construction of machines and makes projects successful from start to finish.

Optimal project management for department managers in plant engineering with COMAN

COMAN offers great benefits to plant engineering department managers, including pre-fabrication, assembly, production and commissioning managers.

COMAN optimizes task coordination and collaboration between teams. It simplifies the transparent and reliable management of commissioning and the clear definition and tracking of project goals in terms of quality, deadlines and costs.

Efficient construction management with COMAN: digital monitoring and reports

As a site manager or construction site supervisor, you can use COMAN to collaborate efficiently within the construction site team, digitally monitor construction progress, create digital protocols and easily record open points and digital reports.

COMAN is the construction site management system for transparent monitoring, control and coordination of all those involved in the construction of machines and systems.

Efficient project management with COMAN software for project managers, planners, coordinators and schedulers in the plant engineering industry!

With COMAN, project managers benefit from seamless team integration and effective collaboration. The platform enables clear roles, rights and responsibilities to be assigned so that everyone knows exactly what needs to be done. Open points can be optimally tracked and processed, deadlines can be coordinated with suppliers and checklists can be tracked precisely to keep an eye on project progress at any time. Optimize your project management with COMAN and experience the difference!

Optimized quality ensure with COMAN

With COMAN, quality managers can easily track, record and report open issues on site via a mobile app. Photos, videos, comments and detailed descriptions of problems can be added to the app. In addition, checklists can be filled in.

COMAN is the construction site management system for the transparent monitoring, control and coordination of all parties involved in the construction of machines and systems.

Digital progress in plant engineering with COMAN

COMAN offers assembly teams in plant construction decisive advantages through digital planning, control and monitoring of pre-assembly through to final assembly on site at the customer's location. The software facilitates the creation of digital documents, shows clear workflows and enables the targeted filtering of relevant data. COMAN thus provides effective support in increasing quality and reducing errors throughout the whole assembly process.

Smooth cooperation and uncomplicated scheduling for suppliers

With COMAN, suppliers and clients can work together on a collaborative platform without much effort, request changes to deadlines and document progress easily via app. With COMAN, there is no longer a need to use countless emails or Excel lists as reports.

Book now a free meeting with our team!

Any questions? Feel free to contact us any time:

E-Mail: sales@coman-software.com

Your specialties

Our key features

Supplier Management

Real-time coordination of various unknown trades and suppliers

Efficient Construction Site Management

Stable collaboration between client and contractor

Avoid Undesirable Developments

Identify deviations from the plan immediately and rectify them at an early stage

Milestone Planning

Digitally approve and release achieved goals and completions

Software

Monitor and control complex software rollout projects worldwide

Optimization and Improvement

Using operating data from the "digital project twin" for continuous improvement of plant and machinery

Assembly and Installation

Digitally plan and accompany the pre-assembly in the factory up to the final installation on site

Conception and Planning

Developed concepts, created plans fully implemented into the system

Quality Management

Provide, monitor and control digital checklists, protocols or measurement reports centrally

Maintenance

Record and assign open items on a mobile basis and monitor processing

Plant Acceptance

Designing digital buy-off and acceptance processes securely and simply

Commissioning

Transparent and secure control of start-ups or ramp-up projects

Test Benches

Digitally process checklists for the conversion of test benches

Plant and Building Design

Monitor and control factory planning projects

Large-Scale Machine Manufacturing

Project management for the entire machinery life cycle

Shutdown Management

Plan, implement and accept large maintenance projects or small tasks efficiently

...and many more

What our customers say

"High standardisation, shorter phone calls, more structured on-site execution!"

“Problems can not be planned”

"Others knowing about our adherence to schedules (...)gives us clear advantages."