Efficient planning and project management for the construction and conversion of commercial vehicle production lines

Greater transparency, flexibility and efficiency with COMAN

Efficient line conversion in commercial vehicle production - digital project management for success

The commercial vehicle industry is under massive pressure to transform. Inefficient processes and a lack of transparency often result in high costs, particularly when it comes to the construction and conversion of production lines.

This white paper shows how a digital solution such as COMAN connects all project participants, optimizes processes and thus saves time and resources - for future-proof, lean production.

Our topics

- Industry change under pressure: CO₂ targets, new technologies and global competition demand rapid adaptation.

- Time and cost pressure: Complex projects in the production environment have to be implemented faster and more cost-effectively.

- Planning problems: Inefficient processes, a lack of transparency and weak coordination are hindering the conversion of production lines.

- Digitalization as a lever: Digital solutions such as COMAN enable real-time transparency and better collaboration.

- Efficient conversion: COMAN significantly reduces costs and times in the set-up process - flexible, networked and future-proof.

Preview

Take a first look at our white paper now

Digital efficiency in commercial vehicle construction: smarter control of production conversions

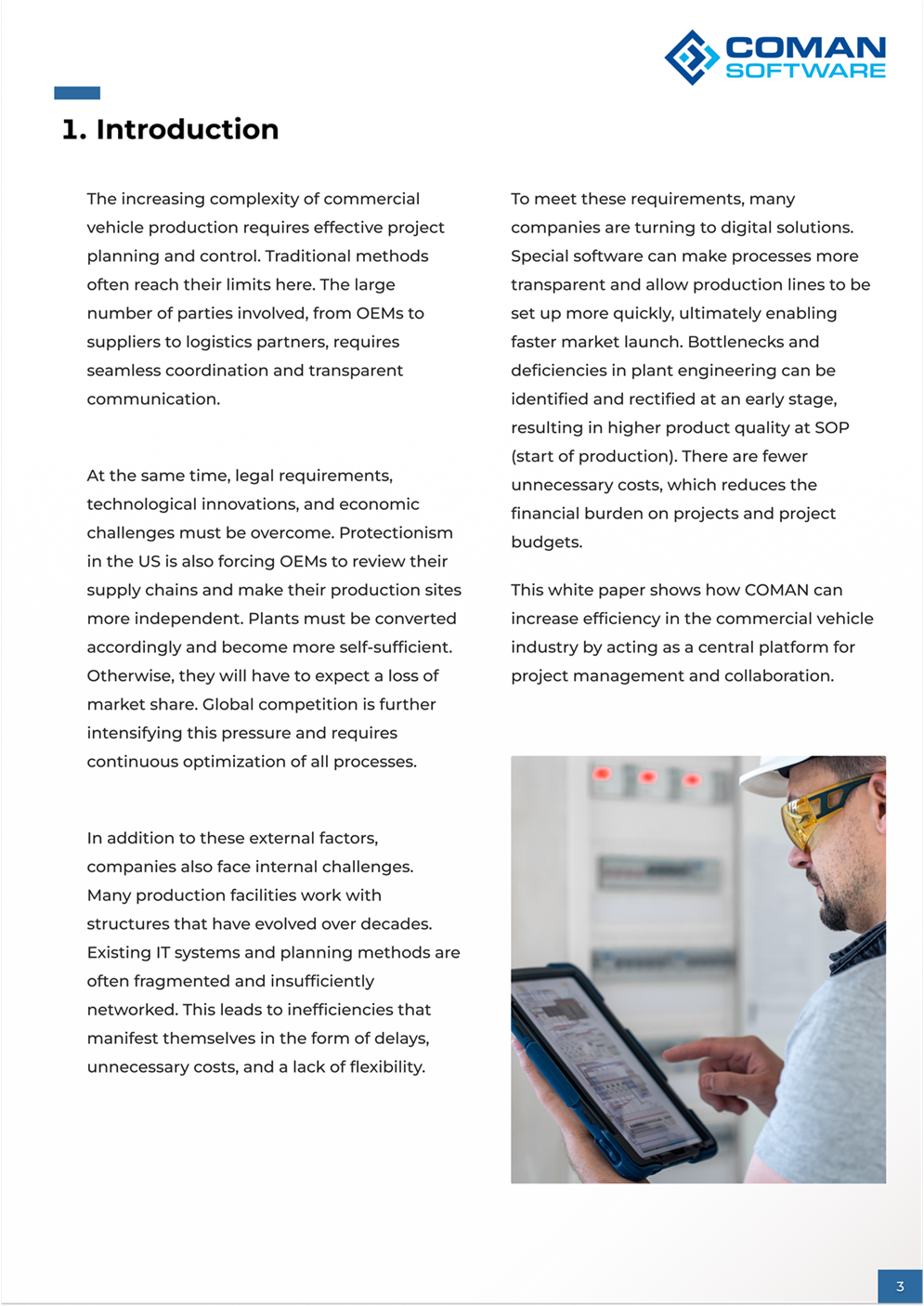

The commercial vehicle industry is under massive pressure to change: CO₂ targets, technological upheaval and increasing time and cost pressure demand new solutions. Inefficient set-up processes and a lack of coordination hinder complex projects.

COMAN offers a digital platform that improves transparency, efficiency and collaboration when setting up and converting production lines. With real-time data and standardized processes, COMAN strengthens competitiveness - today and in view of future challenges such as electromobility and automated production.

CO₂ targets & new mobility

Electrification & automation

Projects must be implemented more quickly

Efficiency becomes a survival factor

Planning often inefficient

OEMs, suppliers, partners not synchronized

Digital platform for clear processes

Transparency & digitalization as the key