Anwenderbericht

Valiant TMS Group (2)

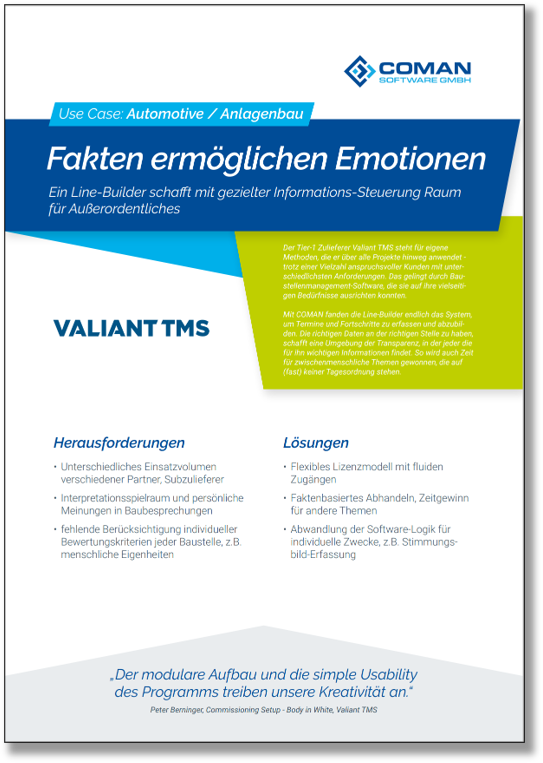

Use Case: Automotive / Anlagenbau

Als globaler Anbieter von intelligenten Automatisierungssystemen spielt Valiant TMS eine Schlüsselrolle im internationalen Automobilanlagenbau. Die TMS Turnkey Manufacturing Solutions GmbH – das organisatorische Nervenzentrum der Gruppe in Europa – entwickelt, baut und integriert automatisierte Produktionssysteme und Werkzeuge für alle Rohbaubereiche.

Entdecken Sie, wie vom Linzer Standort aus international übergreifende Herausforderungen gesteuert werden.

Zum Anwendungsfall

Der Tier-1 Zulieferer Valiant TMS steht für eigene Methoden, die er über alle Projekte hinweg anwendet. Erfahren Sie, wie die Line-Builder ihr System gefunden und etabliert haben, um Termine und Fortschritte zu erfassen, verschiedene Abhängigkeiten einfach abzubilden und mit reduzierter Komplexität an die Beteiligten auszusteuern. Dabei wird nicht nur Zeit gespart, sondern Aufmerksamkeit für Themen gewonnen, denen oft zu wenig Beachtung geschenkt wird.Dieser Anwenderbericht ist für

- Karosserie- und Linienbauer

- Automationsspezialisten

- Automobilzulieferer

- Baustellenleiter

- Baustellenkoordinatoren

- Projektmanager

- Teamleiter

„Der modulare Aufbau und die simple Usability des Programms treiben unsere Kreativität an.“

Commissioning Setup – Body in White, Valiant TMS

Peter Berninger

Herausforderungen

- Hoher Aufwand und Fehleranfälligkeit bei analogen Checklisten

- Umkämpfter Wettbewerb zwischen Zulieferern im automotiven Anlagenbau

- Unterschiedliche Benennungen auf verschiedenen Servern

Lösungen

- Effizienz und Unmissverständlichkeit mit digitaler Datenerfassung

- Vorsprung durch Nutzung des Tools, das bei OEM zunehmend verbreitet ist

- Software als Übersetzer zwischen den Datenbanken

DOWNLOAD